Rare Skills & Authenticity

Let us take you through the process…

Classic With A Twist

It’s all in the detail. Our collections draw on the history of equestrian design bridging traditional techniques with contemporary design and style. We add authentic detail such as ‘Caramelo’ stitching and punched leather brogue design to natural and treated leathers to create modern interpretations of the classics.

Vegetable dye leathers ready for cutting

Boot lasts and leather uppers

Classic twists

Cutting The Patterns

Cutting the patterns is a skill itself. Although we sew on machines and use heavy machinery, we consider our products to be made by hand - many skilled hands. This is how we sew & reinforcing the boot uppers.

Cutting and preparing the patterns

Trocel die cutters for leather insoles

Our signature scalloped edges

Sewing & Reinforcing

The leather components are ready for sewing

The pattern pieces are stitched together

All our boots and shoes are handcrafted

Our Goodyear Welt Construction

Here below, follow the Goodyear welt process - a footwear construction most commonly associated with traditional men’s shoes. The majority of our collection is produced using this construction, ensuring that our styles have flexibility, comfort and longevity. Soles and heels are added.

Adding the counter to the heel for reinforcement

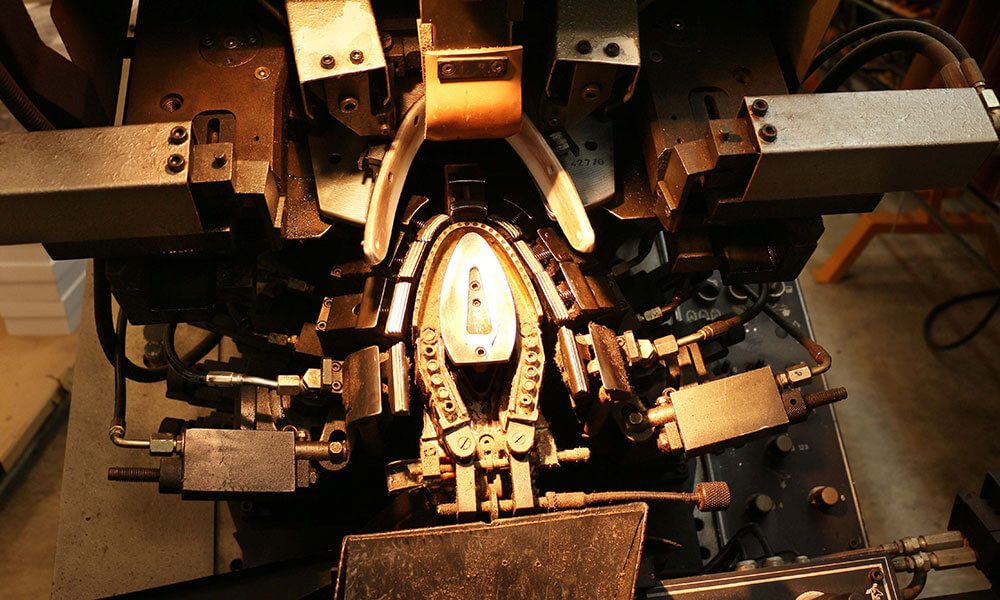

Once sewn, the upper is lasted using the lasting machine

The welt is added

The gap between the sole and the insole is filled with a cushion of cork for comfort

Soled and heeled

Every sole is embossed using our brand dye

Our logo is a symbol of the creative process, everything starts up in the air

Handcrafted heels

Our signature brand ribbon is stitched in

The soles are protected

Hey presto!

Boxing up

Our products are finished by hand with love and care. We choose to manufacture close to home, in Spain, to keep our carbon footprint low. Only biodegradable materials are used in our packaging and we never pack with plastic. Leather and fabric offcuts are never thrown away but used instead to create new products for our seasonal Waste Not Want Not collections.

Leather off-cuts are saved to allow minimum wastage

The boots are wrapped in tissue

Packaged up and ready to go!